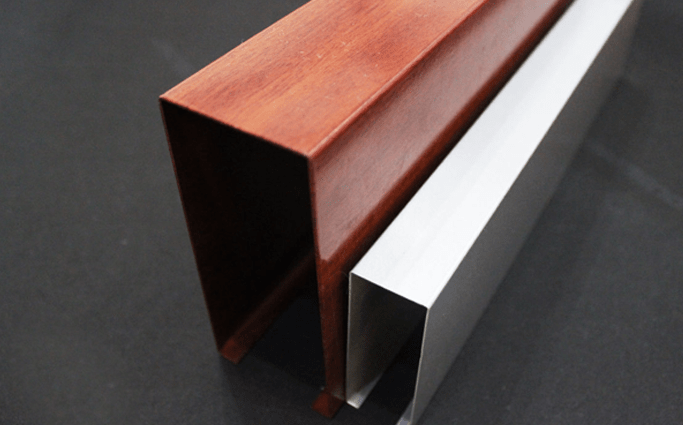

HOW IT WORKS ?

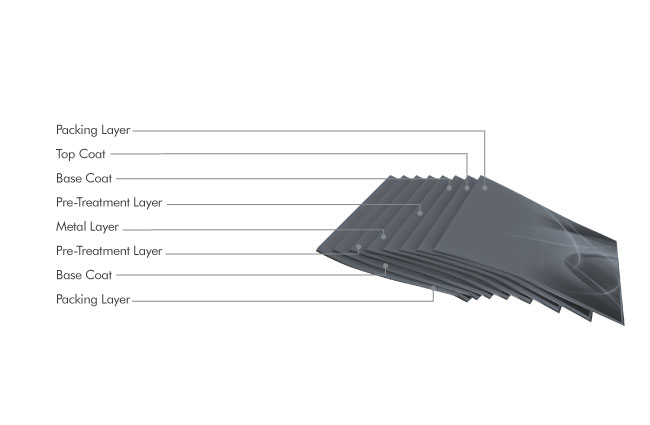

Pre-treatment: The first step in the development of woodentials involves cleaning the base metal of oils, dirt and other impurities deposited on the metal. A non-acidic and environmentally sustainable pre-treatment chemical coating is then applied, that further protects the base, increases the life of the metal and improves powder adherence. Base-coat: In this phase paint in the form of a high quality powder is transferred onto our pre-treated durable metal base electrostatically and then cured. The durable powder that further enhances the quality of the base metal, also allows you to have a wide variety of products in matte or gloss finishes. Top-coat: It is during this stage that we apply our unique wood texture to our product. This is where woodentials acquires its proprietary wood feel and becomes woodentials!

ADVANTAGES OF WOODENTIALS

TECHNICAL DETAILS

Coating Properties

|

Particulars |

Test |

Standard |

Values |

|---|---|---|---|

| Hardness | Wolf-Wilborg Buchholz |

ASTM D 3363 ISO 2815 |

H2H 80 |

| Adhesion | – | ISO 2409 | GT 0 |

| Film Thickness | – | ISO 2306 | 60 ± 10 µm |

| Deep Impact | – | ISO 6272 | 25 Kg. cm |

| Reverse Impact | – | ISO 6272 | 25 Kg. Cm |

| Erichsen Cupping Test |

– | ISO 1502 | 5 mm |

| Umidity Chamber* | – | ISO 6270 Qualicoat |

Complies with requirements |

| Salt Spray Test* | – | ISO 9227 Qualicoat |

Complies with requirements |

| Bending | – | ISO 1519 | |

| Specific Properties | CASS-TEST | ISO 9227 (Acetic Salt Spray) |

*Tests to perform onto zinc phosphate steel or chromate treated aluminium plates.

Material Properties

| Material Thickness |

Aluminium 6063-T6 2mm |

|

Component |

Wt. % |

|---|---|

| Al | Max 97.5 |

| Cr | Max 0.1 |

| Cu | Max 0.1 |

| Fe | Max 0.35 |

| Others | Max 1.95 |

| Material Thickness |

Aluminium 015 0.65mm |

|

Component |

Wt. % |

|---|---|

| Al | 97.94 |

| Cr | Max 0.2 |

| Cu | Max 0.11 |

| Fe | Max 0.67 |

| Others | Max 1.26 |

Estimated life of galvanized iron sheets

|

Zinc Coating Weight |

Rural |

Tropical Marine |

Suburban |

Urban |

Highly Industrial |

|---|---|---|---|---|---|

| 120 | 6 years | 6 years | 4 years | 3 years | 2 years |

Aluminium alloy 6063/6063A corresponds to the following standard designations and specifications but may not be a direct equivalent:

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|